Three reasons why biodiesel manufacturers should use flexitanks

The biodiesel industry has experienced exceptional growth since 2005, but with rising feedstock prices and increasing global competition, market players must now look to new technologies to optimize their supply chains and cut costs.

There is one technology that can unequivocally do this: flexitanks.

Flexi-what?

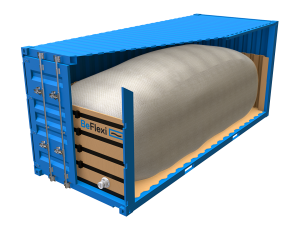

In truth, flexitanks are not a new technology. Their origin dates back to the 1970s when UK shippers tested moving liquids in heavy duty rubberized bladders. The technology has since upgraded and these days, flexitanks are soft bags that fit in standard 20-foot sea freight containers. They can be loaded with any non-dangerous liquid from -20ºC to +80ºC and can fit up to 24,000 liters of this liquid.

Also a young industry, the flexitank sector has seen an unprecedented growth since 2000 and over the past 5 years, there has been double digit growth, which is not set to slow down any time soon. In fact, the current projections are that the global flexitank market will reach USD 922.3 million by 2022.

Flexitanks represent three distinct advantages for manufacturers of biodiesel: supply chain cost-efficiency; risk mitigation; and flexibility.

Standard multi-layer BeFlexi flexitank

More savings

Perhaps the biggest advantage of flexitanks is the cost-efficiency of using them. This cost-efficiency is made all the more valuable with a commodity such as biodiesel because it is one of the few whose raw materials, as well as the finished product, can be transported with flexitanks. That means the potential cost-efficiencies are double.

To illustrate this point, let us look at some operational aspects of flexitanks.

Once flexitanks are installed, they can be loaded with the cargo using a connecting hose and pump – this could take as little as ninety minutes up to two hours – and then immediately sent out for transportation. At the point of destination, the cargo can just as easily and quickly discharged. There is no need for storage or transshipment and, because they are single-use, there is no need for cleaning either. The supply chain is shortened; the cargo reaches its destination sooner; and overall transportation costs are lowered. Easy.

On top of this, flexitanks are 100 percent recyclable and can be disposed of safely and with little to no impact on the environment.

More peace of mind

The longer and more complex the supply chain, the greater the risks are. Increased market volatility and feedstock prices are putting pressure on not only for small manufacturers, but large producers as well. With lots of competition in the biodiesel market, customers are demanding higher quality finished products at lower prices.

Where flexitanks can help is by limiting exposure to this market volatility and combating the risks of price fluctuation. Ordering smaller quantities of feedstock, for example, means a better quality can be sourced, there is no accumulation and less risks of quality degradation. On the flip side, transporting the finished product via flexitanks means again, with smaller shipments, more customers can be reached – and with a larger and more diversified customer base, the risks are spread out. The turnover rates are better and manufacturers can have overall better control over their cashflow – and, importantly, a smaller dependency on financing.

More flexibility

More so than other types of bulk liquid packaging, flexitanks give you the flexibility to source feedstock from anywhere in the world and, at the same time, transport the finished product with ease globally. Flexitanks can be transported by road, rail or sea meaning that even the most inland destinations can be reached.

Additionally, flexitanks and shipping containers are more readily available than ISO tanks and easy to deploy, meaning that producers can order feedstocks as and when needed rather than having to stock large amounts and taking up valuable storage space. Equally, they can respond more flexibly and quickly to customers’ demand for the finished product.

Think flexitank

Managing Director of K.TH.G ECO-LOGICAL FUELS, Dimitris Regginos says, “We transferred from ISO tanks to flexitanks earlier this year. As a producer in such a growing and competitive market, it’s important for us to have an optimized supply chain and, after research, we found that flexitanks were cheaper. Our experience so far has been very positive and they are easy to use.”

There is no doubt that better logistics and an optimized supply chain create value for all players involved and are vital for competitiveness. Furthermore, the biodiesel industry is not slowing down, with new countries in South America and Asia stepping up production, and ever-growing economic and environmental concerns around fossil fuels.

Flexitanks can provide a sustainable and flexible solution to the transportation of both feedstocks and the finished product, thereby reducing costs and hassle. That transportation makes up a big part of the supply chain means this is not to be overlooked.

So why not give flexitanks a try?

Give us a call on +357 2525 4020 or email info@beflexi.com