Simplifying the supply chain with BeFlexi

BeFlexi’s Yan Chizhevskiy features in the latest issue of International Trade Magazine. Below is the interview.

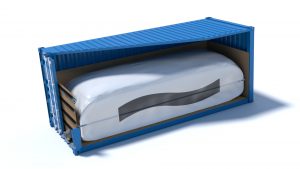

BeFlexi is committed to ensuring cost-effective and comprehensive solutions for transportation and storage to suit any supply chain, as Yan Chizhevskiy, Business Development Director, BeFlexi explains.

BeFlexi is a young company, yet it has a presence around the world – to what does the company owe its success?

The founder of the company, Sergey Galin, once made a joke in a personal conversation, saying: “Yan, do you know why all of these multinational corporations want to work with us around the globe, apart from the fact that we are young and good looking? … Because we know where the money is.” Indeed, the unique thing about BeFlexi is that we are 100% transparent and open with our partners and customers: daily we are explaining to forwarding companies how they can optimise their customer’s logistic expenses by applying the flexitank technology. And respectively, we explain how they, too, can earn more. We consider ourselves an integrator of the industry: ensuring the best supply of products, with the most reliable local services and access to new markets. We are happy sharing our knowledge and expertise: and the strategy is working, as we’re seeing positive results all around the world.

The second thing, which is even more important, is the expertise itself; reliable procedures in place; and the ability to deliver upon the expectations of your customers globally. This has become possible for us thanks to our unique business model and global network of our partner: SGS – the world’s leading inspection, verification, testing and certification company – who have enabled us to do what we do, but on a global scale.

What does it take to succeed internationally in the complex world of solutions for bulk cargo containerisation?

It takes time, effort and resources. For the last two years, BeFlexi has opened stocks of flexitanks (inventories) and set up operations in more than 20 locations worldwide. When you think about it, it’s a short period, but in reality, BeFlexi’s operational excellence dates back to 2008 when the idea was first born. Since then, it’s been a mixture of working really hard (and living in planes!), and being creative enough to use what resources you have to make a relatively young brand, such as “BeFlexi”, be accepted, approved and valued by the most conservative industries: petrochemicals, logistics, etc.

As for the trend of containerisation, on the one hand, the trend in itself helps a lot: cargo owners prefer to diversify their customer base, reach new markets and, ultimately, switch from bulk vessel to flexitanks – the global flexitank market is growing fast (18,6% y-o-y projected till 2022). On the other hand, it’s another challenge, as in order to succeed you need grow faster than the market does.

In what ways does the business show its commitment to bringing logistics technologies to manufacturers and producers around the world?

A good example of our commitment to enabling flexitank manufacturers to produce a better product and secure more business is the special event BeFlexi organised this May in Munich amidst the Transport Logistics exhibition. We invited both flexitank manufacturers (our preferred suppliers), and our customers, whom we provide flexitanks and local services all around the globe. This format allowed the participants to openly share feedback on the products and learn more about new markets and opportunities. As I said, we act as an industry integrator and I really hope to make this event a good annual tradition, opening it out to the wider flexitank industry.

As for the day-to-day business, the Procurement team and I talk to flexitank manufacturers every day to discuss new opportunities, possible design improvements, quality checks and certification matters: it is a very complex and involved process, but we believe it brings positive results to everyone.

How is the company helping to make the logistics industry safer?

This is a great question because quality and safety is something I hold very close and there are several aspects to it.

First of all, we professionalise local flexitank-related services, such as container selection, the flexitank installation inside containers, flexitank loading supervision, emergency services, disposal and so on. Sometimes market players focus too much on cost-optimisation and outsource local flexitank services to agents, who can do it cheaper, but not necessarily in a professional, or even safe, way. It is strange, because percentage-wise the absolute majority of incidents in the flexitank industry are caused by poor local handling. In cooperation with SGS, we offer the market the most secure, reliable and standardised professional services worldwide, no matter what the country and port of loading are.

Secondly, we cooperate with a number of international organisations and I’m personally involved in working on developing standards, coining best practices and putting together the guidelines for the responsible use of flexitanks. For instance, BeFlexi is proud to be a member of the COA (Container Owners Association) Technical Working Group for flexitanks, developing the standards for flexitank manufacturing facilities, which are aimed at making the industry safer. It’s exciting because it’s such a young industry and you really feel that, even though BeFlexi can be seen as a smaller player compared to some, we have the opportunity to shape its future and do something exceptional.

Thirdly, we are on a daily basis, improving internal standards and operational processes: recently we have issued a whitepaper “A new dawn for the flexitank industry” (free for download at www.beflexi.com), which addresses a number of safety issues in the modern flexitank industry.

How popular are your Custom-made Flexitanks within the market?

I would say customers are looking for the right solution, rather than custom-made flexitanks. It is the flexitank operator’s job to provide the client with a solution, including the flexitank, which is the most suitable for their cargo, loading and discharge method. And sometimes the required solution can be defined by geography. For example, if in the case of export of palm oil from Malaysia, the customer is likely to need a heating pad to melt the solidified cargo at discharge, whereas if it is a bulk wine export from Latin America, the flexitank should be equipped with an oxygen-barrier to prevent the oxidation of the cargo.

What trends are you noticing within your industry?

The most obvious one is that the market is booming: more and more cargoes are migrating from bulk vessels, ISO tanks, drums, IBCs.

The second is a consequence of the first one, in that there are more and more players who are trying to launch themselves in the flexitank market. Healthy competition is always good of course, but at the same time, not every new flexitank operator addresses safety issues in the same way as BeFlexi does, which may cause damage to the industry’s reputation. There’s more on this in our whitepaper and is why developing industry-wide, accepted standards is of imperative importance.

Another interesting trend is that, being a niche segment of the container market, the flexitank market with every coming day attracts more and more global logistic container companies, who can secure good freight rates and the right equipment (because not every container is suitable for flexitank shipments) from shipping lines. BeFlexi has, for the past 18 months, been in talks and working with a number of global freight forwarding companies, and it’s now the right time to seek one global exclusive partner.

In what ways do you go above and beyond to support customers in their ability to use your products?

The expertise and knowledge that we share, mentioned above, is what our customers truly cherish. We always go above and beyond supporting customers, regardless of the brand of product. A great story to illustrate this happened last year. On 30 December 2016, I received a call from a cargo owner, who was facing flexitank discharge issues in Egypt (right before New Year Eve). I got in touch with SGS Egypt and together we worked without break until we managed to provide the required services and handle the problem in a very short time. Emergency service coordination on New Year Eve, does this count?

How does BeFlexi support the safe transport of petrochemicals?

The shipment of petrochemicals is our core expertise: since the establishment of BeFlexi we have been very strong in this, thanks to our market knowledge and experience. The petrochemical industry, as I mentioned earlier, is extremely conservative, but most of the Majors have already acknowledged the beauty of using flexitanks: Shell, NYNAS, Neste, you name them – all of them are enjoying the benefits of the technology. Typically, those companies have their own wellestablished safety procedures. BeFlexi not only complies with such requirements, but works closely with the industry Majors to develop consistent standards of safe transport of petrochemicals with the use of flexitanks.

What special requirements must BeFlexi fulfil to ensure the transportation of pharmaceutical products in a timely manner?

This question comes down to the technological advantages of flexitanks and liner bags: flexitank is a single-use food-grade (always new) tare. The companies involved in the production and trading of cargoes such as “white oils” (the raw material for pharmaceuticals and cosmetics) usually face issues using ISOtanks because of the cargo that was shipped in those tank-containers before. Even when washed and cleaned, ISO-tanks can spoil the white oil with a smell (while quite often white oils should be odorless).

Flexitank is a perfect solution in this case. Another example, is the thermal liner that can be installed inside the container prior to the flexitank, smoothing down the temperature spikes, which is critical for the shipment of some pharmaceuticals.

How rigorous are the testing procedures put in place for BeFlexi products?

BeFlexi strictly follows implemented procedures of testing, certification and procurement. At the same time, if the product is of a good quality, and the manufacturing facility is in good condition, BeFlexi would be the first party to assist the manufacturer with testing and certification required in order to comply with international market standards. Two years ago when I joined BeFlexi one of the first business trips I made was to Qingdao in China, where we visited more than 15 flexitank manufacturing facilities. Qingdao is the world capital of the flexitank industry, and I certainly learnt a lot from that trip! All of the facilities were supposed to be ISO-certified, and of course, to their credit, some of the them were really clean and tidy with employees wearing uniforms and observing all ISO procedures. However, in others I saw people working in their pyjamas, using scissors to cut polyethylene films. When you’re sitting in an office thousands of kilometers away from your potential suppliers, you do not realise such things. That trip was followed by the audit of more flexitank manufacturing facilities in Turkey, Spain, Germany, etc. Since then BeFlexi has regularly been conducting facility audits and checking raw materials as well as final products against internationally set standards in cooperation with SGS. Today BeFlexi is proud of having a diversified supplier portfolio from all over the world, with the ability to source the highest quality products at the best prices.

About Yan Chizhevskiy

Yan Chizhevskiy, Business Development Director, BeFlexi is a young, bright and ambitious professional in the flexitank industry. He joined BeFlexi in its nascency and was instrumental in developing and shaping the Company. He quickly grew with the company and is now the Business Development Director.

Yan’s responsibilities lie in the strategic development of the Company, identifying new business and investment opportunities and maintaining relationships with key partners. He also oversees procurement activities and works closely with the Operations team to implement digitalisation projects and optimise processes.